Fleming Laboratories’ state-of-the-art manufacturing facilities ensure that we deliver quality and scale. Our dedicated and multi-product manufacturing facilities are well equipped with all the required infrastructure to handle complex chemistries and to manufacture top quality products. Fleming laboratories has two well established manufacturing facilities and one R&D center located in Hyderabad, India Fleming laboratories is also creating two new facilities, one in Telangana and one in Karnataka to supplement their manufacturing capacities.

Unit I

Nawabpet, 40 Km from Hyderabad

- 48000 Sq. Mts

- 5 blocks

- 190 KL total reactor capacity

- 220 employees

- Regulatory Approvals

- EU GMP

- WHO GMP

- PMDA

- COFEPRIS

Unit II

Jeedimetla, Hyderabad

- 2100 Sq. Mts

- 1 block

- 8 KL total reactor capacity

- 60 employees

- Regulatory

- Approvals

- KFDA

WHO GMP

Unit III

Yadagir taluk & district, Karnataka

- 2100 Sq. Mts

- 1 block

- 8 KL total reactor capacity

- 60 employees

- Regulatory

- Approvals

- KFDA

WHO GMP

Unit IV (Fermac Bio)

Medak District, Telangana

- 20000 Sq. Mts

- 1st block under construction(total plan of 2 production blocks)

- 200 KL reactor capacity (for 1st block)

- 64 employees (phase 1)

- Regulatory Approvals

- Operations to start from March 2024

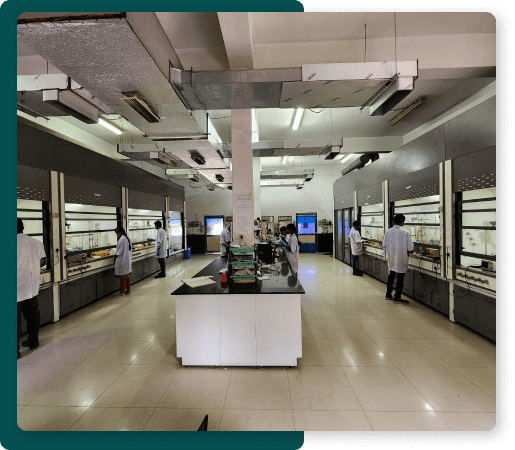

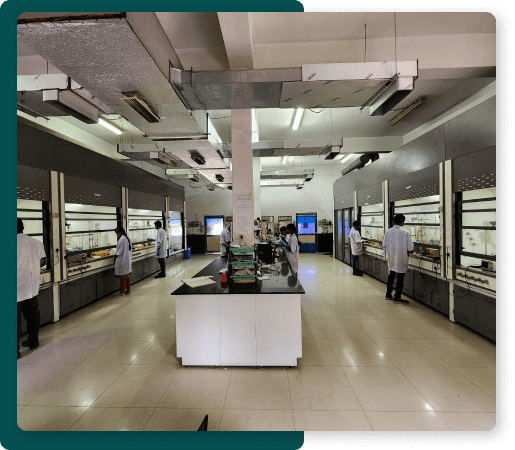

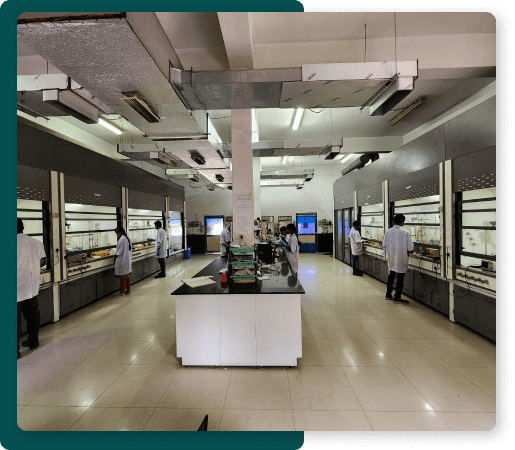

Our team of highly qualified research scientists bring in depth of knowledge and experience to our engagements. Fleming R&D centre is accredited by the Government of India (DSIR).

- 18 member R&D team led by senior R&Dprofessionals

- Dedicated Infrastructure with 8 fume hoods (Expansion to 16 fume hoods in progress)

- Capability to handle wide range of chemistries

- Strong IP knowledge

- Integrated tech transfer and EHS risk assessment team

- Expertise in process development, impurity profiling, synthesis and characterization

- Expertise in Regulatory Query resolutions

- Expertise in current regulatory expectations like Genotoxic impurities assessment, Nitrosamine impurities assessment, etc.

Objective

- Develop environmentally friendly and safe processes

- Quick turnaround time (product identification to market)

- Development of robust processes (detailed stress studies on process parameters)

Our highly experienced manufacturing team ensures that we deliver the right quality product in time.

Our Manufacturing Capabilities Includes:

- Highly experienced manufacturing and Engineering team

- Robust planning process driven by customer demand

- Wide range of process equipment supporting the chemistries handled

- Wide range of Utility equipment to support the critical process parameters

- Zero liquid discharge effluent treatment system

Objective

- Delivering the products, on-time to the customers

- Operational excellence through continuous improvement

- Zero accidents and incidents

Quality Assurance

- Quality management system and documentation in line with ICH

- System backed up by continuous training of personnel

- Regular Internal Quality Audits and supplier audits to ensure that products meet quality consistently

Quality Control

- Well trained and experienced team

- Comprehensive and integrated analytical capability

- Electronic data management as per 21CFR part 11

Objective

- Do it right the first time every time

- Zero market complaint

Fleming Labs’s experienced team of Regulatory experts maintain an active channel of communication with regulatory agencies across the globe.

Our expertise in regulatory affairs enables us to address and respond quickly and promptly to all aspects concerning regulatory submissions. The team keeps track and updates itself of evolving regulations across various agencies.

Regulatory Capabilities:

- Preparation of DMFs

- Filing variations & updates

- Response to deficiencies within stipulated timelines

Objective

- Response in time

- Infrastructure

- Research & Development

- Manufacturing

- Quality Management

- Regulatory Support

Fleming Laboratories’ state-of-the-art manufacturing facilities ensure that we deliver quality and scale. Our dedicated and multi-product manufacturing facilities are well equipped with all the required infrastructure to handle complex chemistries and to manufacture top quality products. Fleming laboratories has two well established manufacturing facilities and one R&D center located in Hyderabad, India Fleming laboratories is also creating two new facilities, one in Telangana and one in Karnataka to supplement their manufacturing capacities. Nawabpet, 40 Km from Hyderabad Jeedimetla, Hyderabad Yadagir taluk & district, Karnataka Medak District, Telangana Nawabpet, 40 Km from Jeedimetla, Yadagir taluk & district, Medak District,

Unit I

Unit II

WHO GMP

Unit III

WHO GMP

Unit IV

Unit I

Unit II

Unit III

Regulatory ApprovalsUnit IV (Fermac Bio)

Unit I

Hyderabad

Unit II

Hyderabad

Unit III

Karnataka

Unit IV (Fermac Bio)

Telangana

Our team of highly qualified research scientists bring in depth of knowledge and experience to our engagements. Fleming R&D centre is accredited by the Government of India (DSIR).

- 18 member R&D team led by senior R&Dprofessionals

- Dedicated Infrastructure with 8 fume hoods (Expansion to 16 fume hoods in progress)

- Capability to handle wide range of chemistries

- Strong IP knowledge

- Integrated tech transfer and EHS risk assessment team

- Expertise in process development, impurity profiling, synthesis and characterization

- Expertise in Regulatory Query resolutions

- Expertise in current regulatory expectations like Genotoxic impurities assessment, Nitrosamine impurities assessment, etc.

Objective

- Develop environmentally friendly and safe processes

- Quick turnaround time (product identification to market)

- Development of robust processes (detailed stress studies on process parameters)

Our team of highly qualified research scientists bring in depth of knowledge and experience to our engagements. Fleming R&D centre is accredited by the Government of India (DSIR).

- 18 member R&D team led by senior R&Dprofessionals

- Dedicated Infrastructure with 8 fume hoods (Expansion to 16 fume hoods in progress)

- Capability to handle wide range of chemistries

- Strong IP knowledge

- Integrated tech transfer and EHS risk assessment team

- Expertise in process development, impurity profiling, synthesis and characterization

- Expertise in Regulatory Query resolutions

- Expertise in current regulatory expectations like Genotoxic impurities assessment, Nitrosamine impurities assessment, etc.

Objective

- Develop environmentally friendly and safe processes

- Quick turnaround time (product identification to market)

- Development of robust processes (detailed stress studies on process parameters)

Our highly experienced manufacturing team ensures that we deliver the right quality product in time.

Our Manufacturing Capabilities Includes:

- Highly experienced manufacturing and Engineering team

- Robust planning process driven by customer demand

- Wide range of process equipment supporting the chemistries handled

- Wide range of Utility equipment to support the critical process parameters

- Zero liquid discharge effluent treatment system

Objective

- Delivering the products, on-time to the customers

- Operational excellence through continuous improvement

- Zero accidents and incidents

Our highly experienced manufacturing team ensures that we deliver the right quality product in time.

Our Manufacturing Capabilities Includes:

- Highly experienced manufacturing and Engineering team

- Robust planning process driven by customer demand

- Wide range of process equipment supporting the chemistries handled

- Wide range of Utility equipment to support the critical process parameters

- Zero liquid discharge effluent treatment system

Objective

- Delivering the products, on-time to the customers

- Operational excellence through continuous improvement

- Zero accidents and incidents

Quality Assurance

- Quality management system and documentation in line with ICH

- System backed up by continuous training of personnel

- Regular Internal Quality Audits and supplier audits to ensure that products meet quality consistently

Quality Control

- Well trained and experienced team

- Comprehensive and integrated analytical capability

- Electronic data management as per 21CFR part 11

Objective

- Do it right the first time every time

- Zero market complaint

Quality Assurance

- Quality management system and documentation in line with ICH

- System backed up by continuous training of personnel

- Regular Internal Quality Audits and supplier audits to ensure that products meet quality consistently

Quality Control

- Well trained and experienced team

- Comprehensive and integrated analytical capability

- Electronic data management as per 21CFR part 11

Objective

- Do it right the first time every time

- Zero market complaint

Fleming Labs’s experienced team of Regulatory experts maintain an active channel of communication with regulatory agencies across the globe.

Our expertise in regulatory affairs enables us to address and respond quickly and promptly to all aspects concerning regulatory submissions. The team keeps track and updates itself of evolving regulations across various agencies.

Regulatory Capabilities:

- Preparation of DMFs

- Filing variations & updates

- Response to deficiencies within stipulated timelines

Objective

- Response in time

Fleming Labs’s experienced team of Regulatory experts maintain an active channel of communication with regulatory agencies across the globe.

Our expertise in regulatory affairs enables us to address and respond quickly and promptly to all aspects concerning regulatory submissions. The team keeps track and updates itself of evolving regulations across various agencies.

Regulatory Capabilities:

- Preparation of DMFs

- Filing variations & updates

- Response to deficiencies within stipulated timelines

Objective

- Response in time